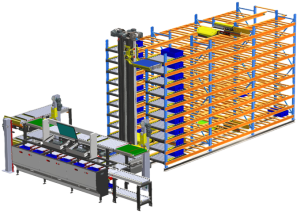

Operation of the automatic product distribution system

The system called Rabbit is a Goods-to-person system. It functions from storing products, processing product orders, picking products, and transporting them for employees to pick. When picking products, there will be a command on the screen for employees to pick products according to the specified quantity. Picking products will pick 4-6 items at a time. To make work faster, the system will help guide the picker to work easily and have a warning system in case of picking the wrong one. When each product order is picked completely, all products will be transported and sent to the inspection and packing area to check the picked products with the product order before sending them to the customer.

How does RABBIT help reduce costs?

- Save space, by using vertical space, allowing more products to be stored in a limited area.

- Reduce the use of manpower for pick and store products is reduced.

- Better inventory control, helps to manage and control inventory accurately, reducing the problem of lost or expired products.

- Increase work efficiency, helps reduce the time spent searching and picking products, making the work process faster and more efficient.

- Reduce errors, helps reduce human errors in storing and issuing products, the system is highly accurate and precise.

- Reduce training time, employees do not need to be trained in picking products.

- Improve customer service.

- Fast and accurate product management helps to better meet customer needs.